Installation Housings XL-Series

Throughly thought through to every corner

Installation Housings XL-Series

Time-saving, clever and usable anywhere

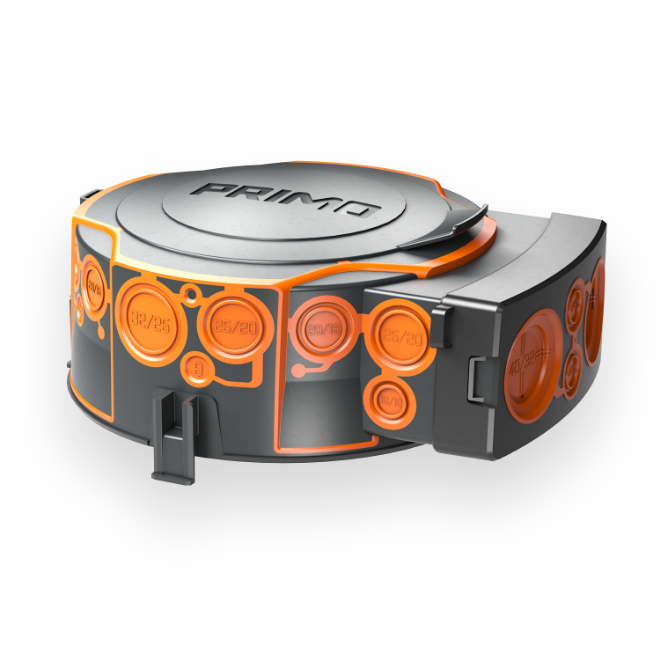

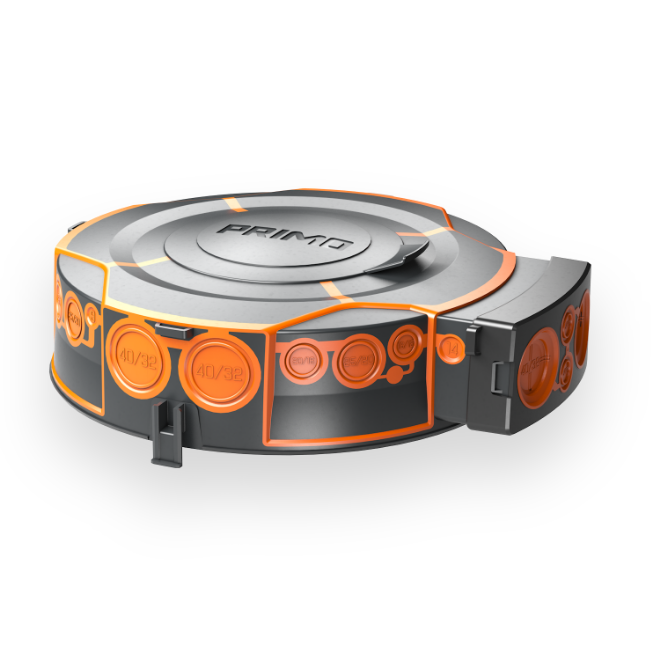

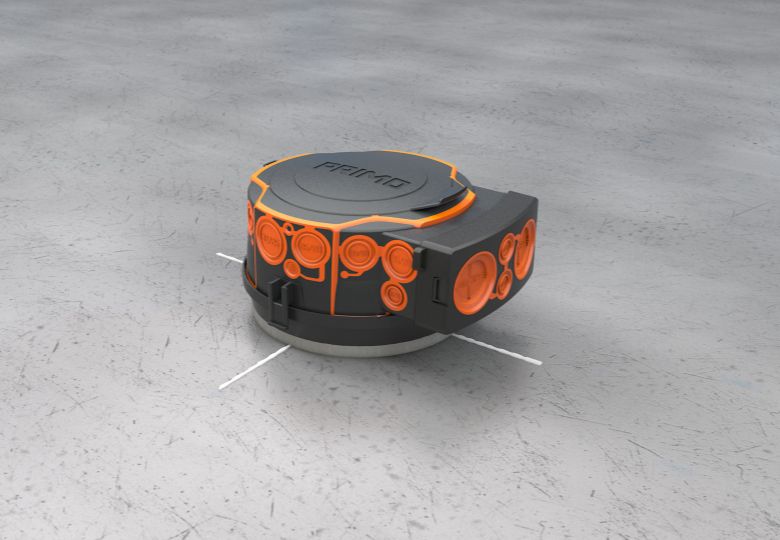

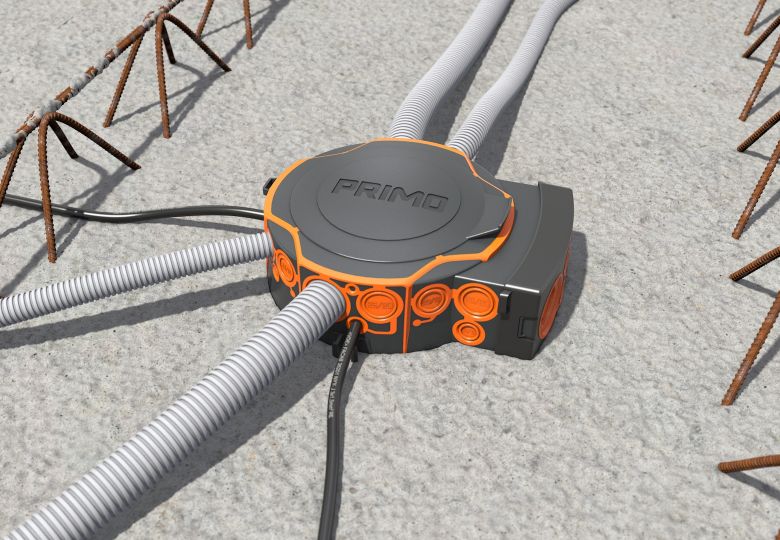

Absolutely concrete-tight, mounted in seconds and with numerous possible applications. With the new XL-Series installation housings, Primo has developed allrounders that are perfect for mounting all special installation housings – from luminaires to loudspeakers to other built-in components. The probably greatest advantage for precast factories: The XL 200 and the XL 250 can be attached with a magnet. This saves a lot of time in production and also delivers a high-quality product. The perfect material for your perfect prefabricated slab.

And Action!

Installation housings XL-Series

Winner of the

Red Dot Design Award!

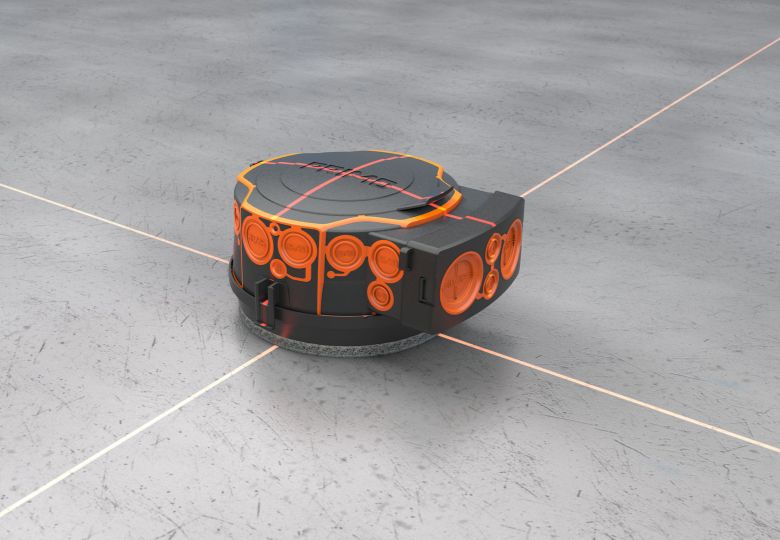

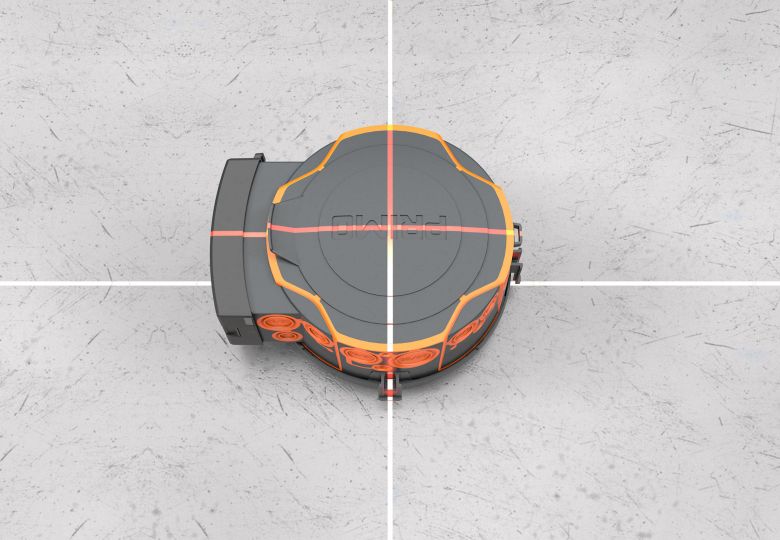

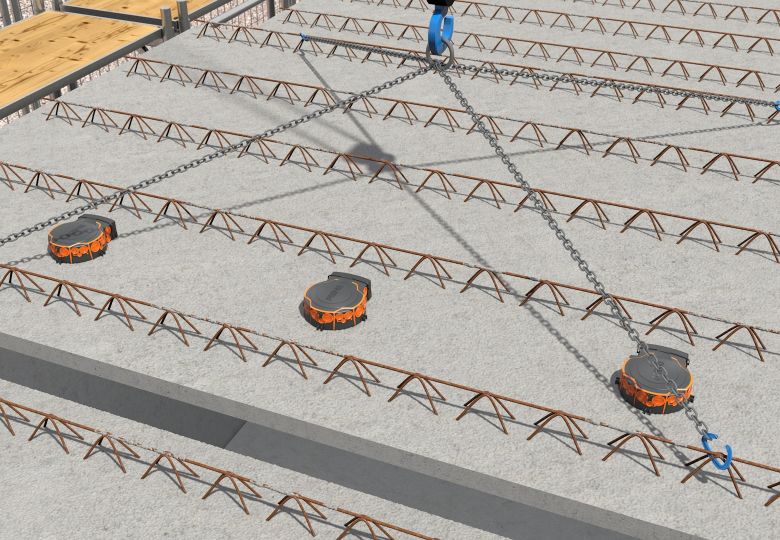

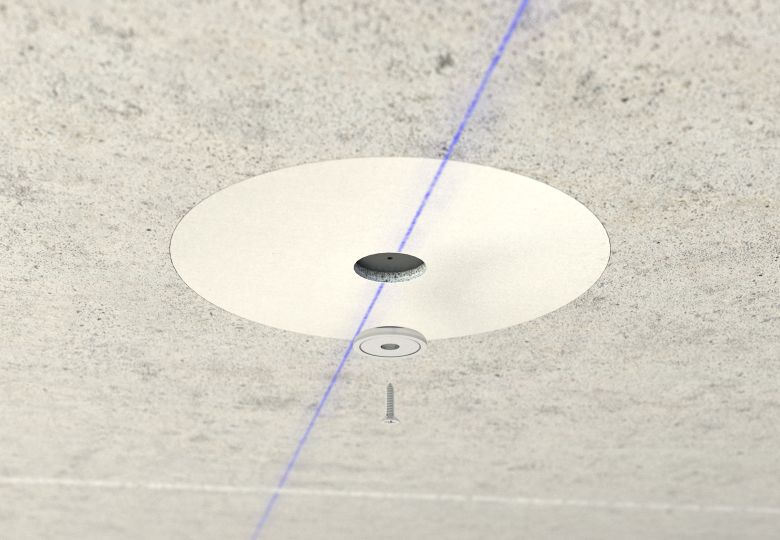

Beside the classic attachement with glue and a mineral fiber board the installation housings can be positioned on the formwork with an integrated magnet in the universal board – either manually or automatically in the precast factory. In addition to a higher quality of the final product, bothersome removal of glue residue is no longer necessary. On top of that are the magnets recyclable and therefore more environmentally friendly compared to conventional methods. The magnets remain in the installation housings and the electrician can simply remove them on the construction site in order to return them to the cycle via the magnet recycling.

With at least 25 entries each, all variants of the XL-Series offer sufficient space for cables or conduits in sizes from M9 to M40. The maximum installation depth of built-in devices in the XL-Series is 110 mm. The halogen-free polypropylene multitalents are heat-resistant from -5 °C to 100 °C. Due to its material, the universal panel is also ideal for outdoor use.

Further technical information can be taken from the data sheets.

Downloads:

XL-Series from Primo

Your advantages in precast factories

Easy assembly

in just a few steps

- Manual attachement with magnet

- Automatical attachement with magnet

- Manual attachement with glue

- Final installation on the construction site

1

Universal Board with an integrated magnet.

2

Precise positioning on the formwork.

3

The installation housing can still be rotated by 360°. Imprecisions can still be easily corrected.

1

XL plate magazine with XL Front Parts is picked up by robot.

2

Front Parts are positioned automatically on the formwork.

3

Reinforcement and cross-irons are being installed.

4

Installation housing is being placed.

1

Glue is being applied on the Mineral Fiber Board.

2

Installation housing is being positioned precisley.

3

Reinforcement is being installed.

1

Prefabricated slab is being delivered and assembled.

2

Open the membrane with a cutter knife.

3

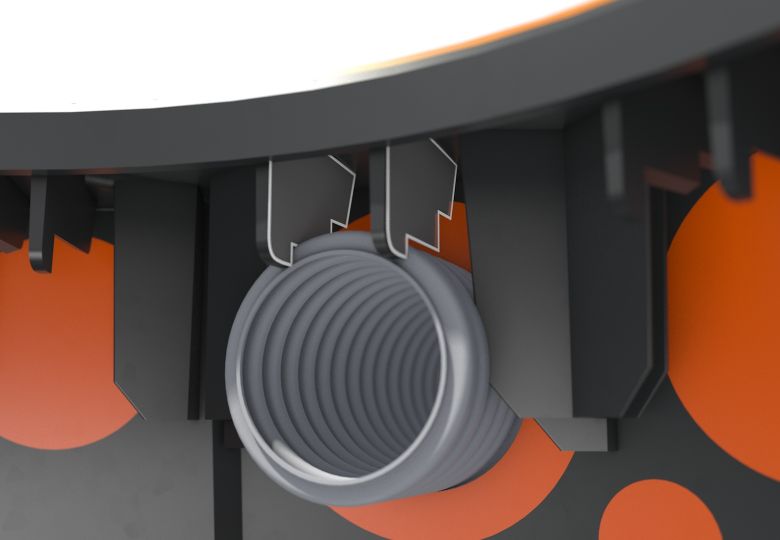

Absolute concrete-tight openings due to membrane technology.

4

No shortening of conduits due the conduit stop.

5

The combination entries offer space for cables and conduits (M9 – M40) without tools.

6

Cables and conduits can be pulled into the Installation housing even before concreting.

7

High impact resistance due to the innovative design.

8

Minor editing on the construction site.

9

Remove magnets and recycle them to save ressources and the environment.

10

Mill individual openings with a carbide cutter.

11

Install any desired built-in device.

Excellent

electrical installation

Our products stand for quality made in Germany. The installation housings of the XL-Series therefore won three design awards in 2022: the internationally renowned Red Dot Award, the Focus Open, the official design competition of the state of Baden-Württemberg, and the design competition of Light and Building, the world’s largest electrical trade fair. In addition to design aspects, the main deciding factors for the awards were functionality, innovation and product quality.

Accessories for XL-Series

YOU MIGHT ALSO BE INTERESTED IN:

Further solutions for precast factories

What are the advantages of the XL installation housing?

Take the product out of the box, place it on the formwork and you’re done! The XL installation housings are absolutely concrete tight, mounted in seconds and offer numerous possible applications. They are perfect for mounting all special installation housings – from luminaires to loudspeakers to other built-in components. The probably greatest advantage for precast factories: The XL 200 and the XL 250 can be attached with a magnet. This saves a lot of time in production and also delivers a high-quality product. The perfect material for your perfect precast part and a satisfied customer.

Is it possible to vary the installation height of the XL installation housing?

The XL 150 Extension Ring and the XL 200 Extension Ring are available for the XL 150 and XL 200 installation housing. The Extension Ring can be attached to the installation housing and provides more installation space thanks to the increase in height. As many Extension Rings can be connected together until the desired installation depth is reached. The plug-in system ensures a quick and stable connection.

Is it possible to add a transformer tunnel to the installation housings of the XL-Series?

Yes, an optional Universal Tunnel is available for the XL 150, XL 200, and XL 250 installation housings. The Universal Tunnel creates additional installation space, ideal for larger electronic components, for example. It can be universally attached to all installation housings in the XL-Series.

The XL 300 installation housing is available in two versions: One with transformer tunnel and one without transformer tunnel.

Can the XL-Series be used for the production of exposed concrete?

Yes, the XL-Series is ideal for exposed concrete. Depending on the area of application, you can choose the right Front Part individually.

Why is the cover removable?

The removable cover allows cables and conduits to be pulled into the installation housing before concreting. Thanks to the integrated membrane sealing lip, everything remains absolutely concrete-tight.

How are the XL-Series installation housings attached to the formwork?

The installation housings of the XL-Series can be positioned using magnets (manually or with a robot) or glued in the classic way.

Do you have any questions about our products? We are there for You