Standardise, automate, increase quality

Solutions for precast factories

Innovations for the smart concrete factory 4.0

Concrete Boxes, Installation Housings & more

Primo embodies progress and innovation through automated and standardized processes in prefabricated concrete. As experts in our field, we continuously strive for further development. We set standards for the future and offer you numerous advantages: Our innovative products give you a decisive competitive edge, counteract the shortage of skilled workers and significantly reduce overall costs. Think about tomorrow today and benefit from future-oriented progress with Primo!

Take the step towards your smart concrete factory 4.0 with us and our excellent product quality.

Primo solutions for the ceiling

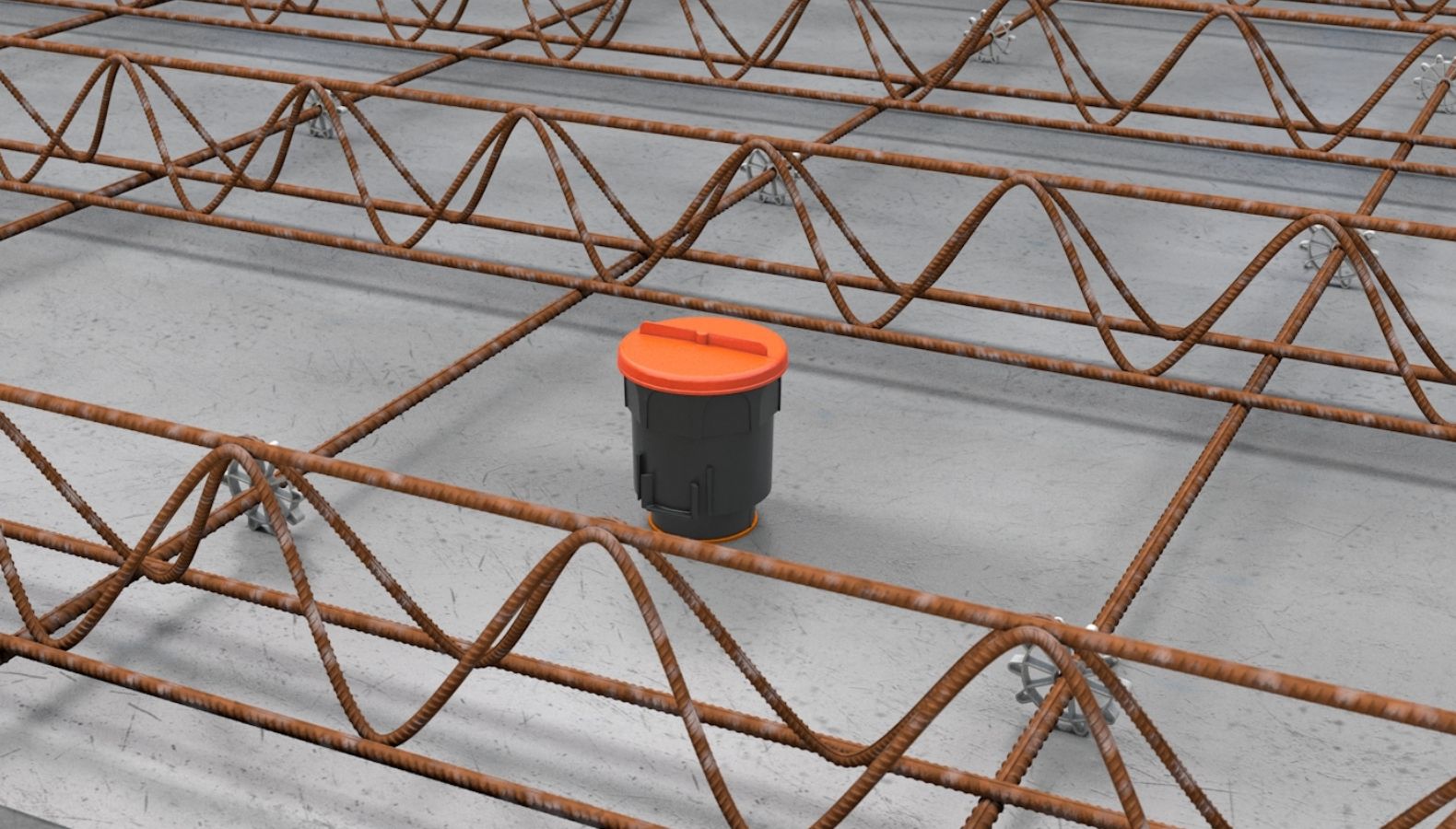

XL-Series

Perfect for individual requirements!

Absolutely concrete-tight, mounted in seconds and with numerous possible applications. With the new XL-Series installation housings, Primo has developed all-rounders that are perfect for mounting all special installation housings – from luminaires to loudspeakers to other built-in components. The probably greatest advantage for precast factories: The XL 200 and the XL 250 can be attached with a magnet. This saves a lot of time in production and also delivers a high-quality product. The perfect material for your perfect prefabricated slab.

Universal Junction Box

Extended intstallation space in the ceiling!

The classic in the production of precast concrete parts! The Universal Junction Box can be used as a ceiling junction box and offers the electrican huge installation space. Thanks to the clever magnet assembly technology, you can deliver high-quality end products in the shortest possible time. See for yourself.

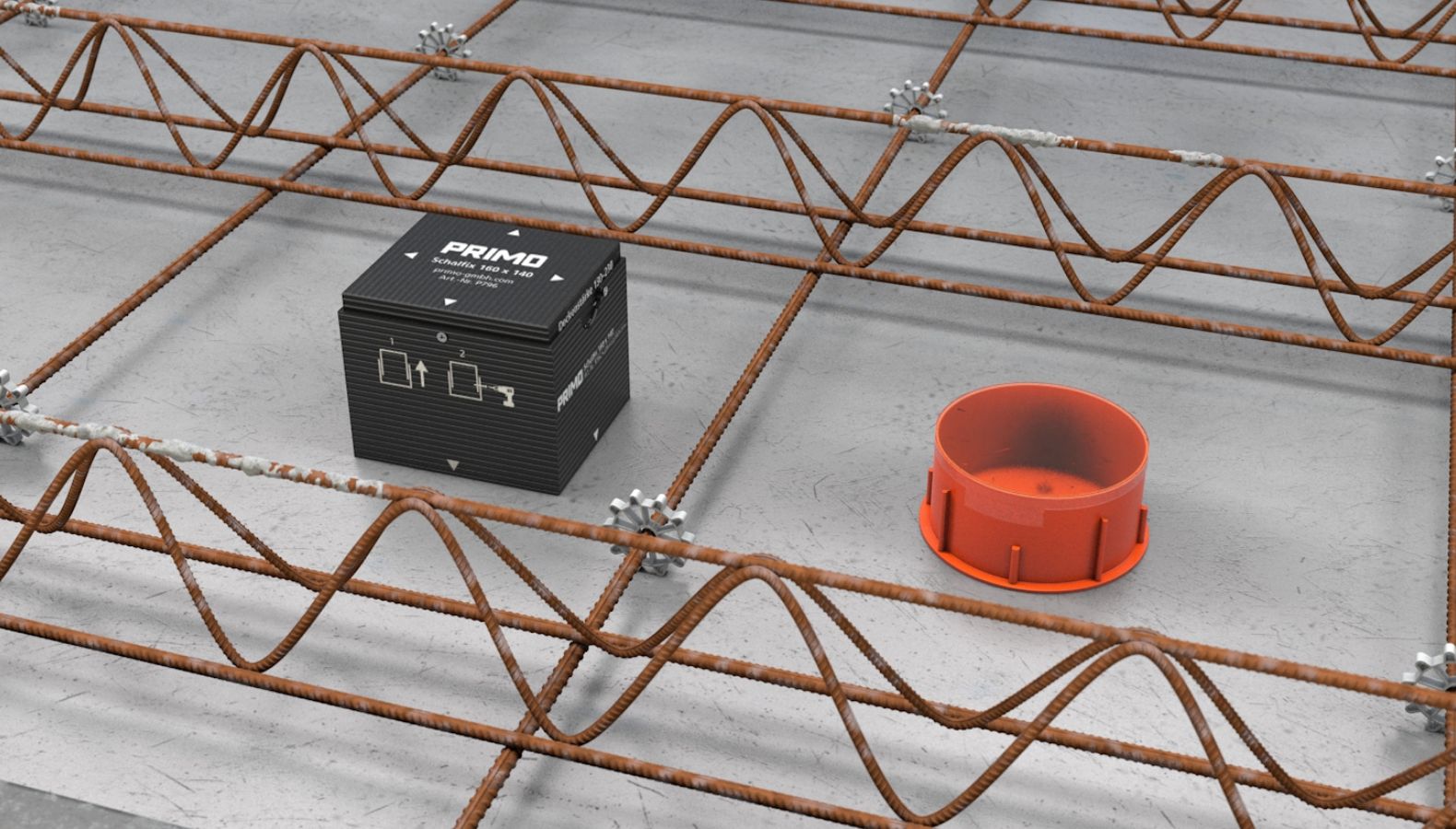

Standardised Special Installation Housings

The time-saving helpers!

The practical Standardised Special Installation Housings facilitate the creation of recesses in prefabricated concrete. Individual and time-consuming wooden or polystyrene cut-outs are now a thing of the past. The Ventilation Sleeve is ideal for ventilation recesses, while the Schalfix is recommended for all other areas of application. Both helpers are installed in seconds and can be easily recycled after concreting. They are therefore also more sustainable than traditional methods.

Uni-Flexx

Retrofitting in ceiling slabs

Correct planning is crucial in concrete construction, because concrete is unforgiving of mistakes – until now. With the Uni-Flexx, you can also retrofit spotlights, loudspeakers or other built-in devices into the already cast filigree ceiling. The required core drill hole is much smaller and therefore significantly cheaper than usual. This increases your flexibility on the construction site and saves you a lot of time and money. See for yourself.

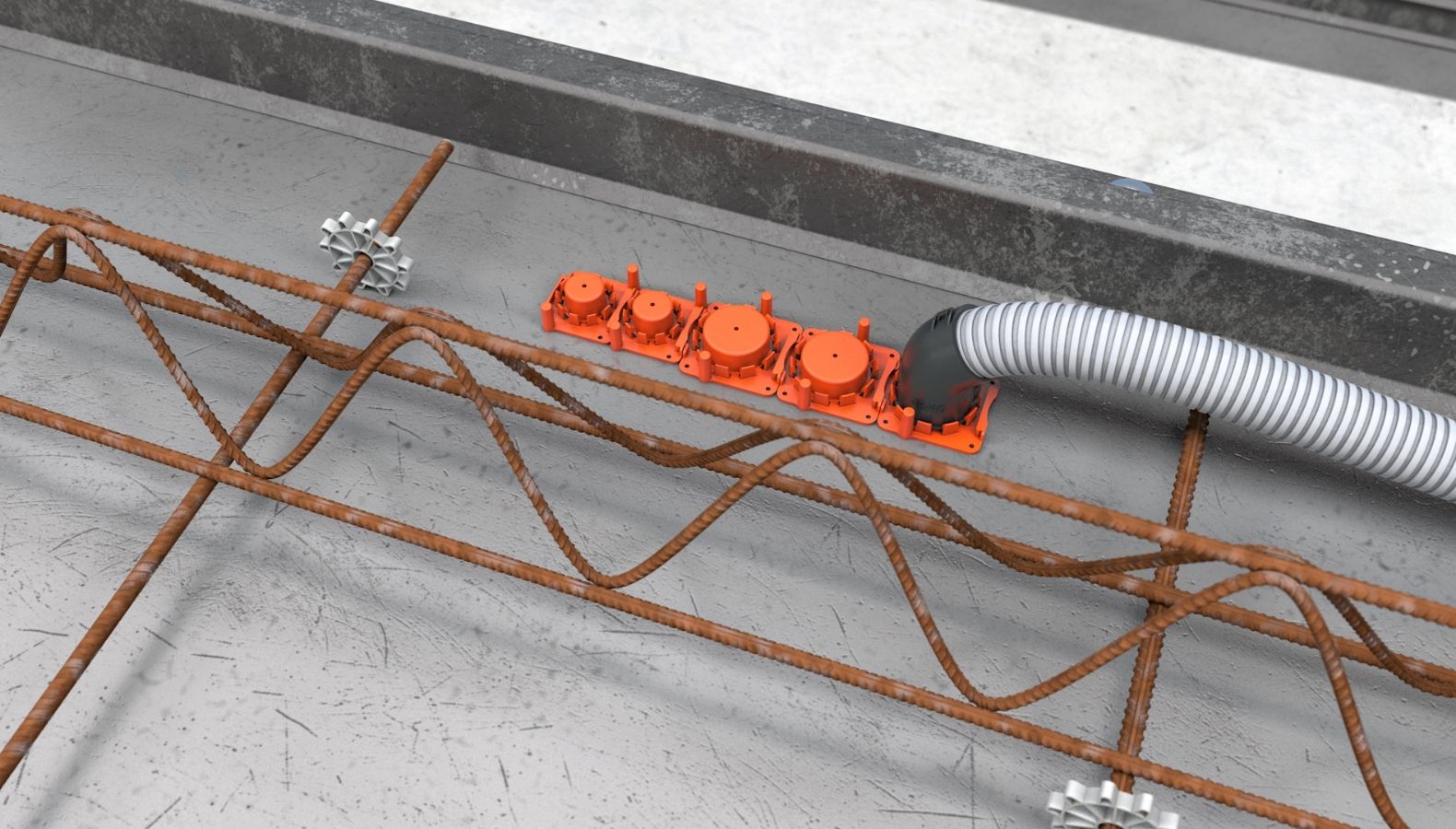

Primo solutions for the wall

M-Series

Concrete boxes for all applications!

With the individually usable concrete boxes of the M-Series you not only save a lot of time in the production of your prefabricated slabs and minimize the storage costs in your precast factory, you also deliver your clients the best possible quality of the final product. The innovative membrane technology of the M1, M2 and M3 boxes is absolutely impermeable to concrete and the conduit grip ensures reliable strain relief. See for yourself!

Wall and ceiling transitions

The practical accessory!

How to really save on storage costs! The new wall & ceiling transitions for concrete construction can be used for two conduit sizes each. Thanks to the 1-for-2 system, different sizes can also be combined with each other. The innovative sleeves and grommets can be stably lined up in just a few simple steps.

UNI-MAGNET hafti®

Brilliant!

One magnet for all built-in parts – fabulous! The Uni-Magnet hafti® is the new solution for optimizing processes and increasing efficiency in precast factories. It fits the complete Primo concrete range and is also compatible with Nevoga cavity wall anchors or Pfeifer inclined column anchors without an adapter. Magnet technology ensures higher quality in the end product and greater added value in your precast factory. In addition, the magnets are reusable and therefore more environmentally friendly than conventional methods.

SCHWABI Slip Guard

The highlight for the thermal wall

The SchwaBi Slip Guard ensures that two wall sections no longer move when they are brought together and are securely positioned in relation to each other. This makes complaints a thing of the past. At the same time, you can significantly increase productivity in your factory with the reusable magnet.

Primo advantages in everyday work

“A complaint is the worst thing that can happen to us. With the Primo products we were able to downscale this significantly. The concrete boxes of the M-Series no longer fill up, because with the integrated strain relief and the guaranteed tightness we have a maximum of security.”

Nieky Smiets, Plant Manager at Weber Betonwerk GmbH

“When using the housings, you notice that a lot of thought was put into the development. Thanks to the magnet technology, we no longer have to glue the housings, which is a huge advantage. On the one hand, bothersome residue has not to be removed on the formwork at all. On the other hand, the product itself is of higher quality.”

Maik Ulrich, Operations Manager DEFEBA GmbH & Co. KG

Is the M1 suitable for all wall thicknesses?

For different wall thicknesses, we have the M1 (installation depth: 85 mm), the M2 (installation depth: 68 mm) and the M3 (installation depth: 48 mm) in our range. A matching Push-on frame extends the box by 2.5 cm for even more installation space.

For narrow luminaire bases, there is also a cover with a 35 mm luminaire outlet for every box in the M-Series.

Which installations can be made with the M1?

With the M1, you have the huge advantage that you only need one box for the entire concrete installation. The M1 can be used as a junction box, concrete wing box, ceiling junction box, large conduit box or electronics box. Not only does this reduce your storage costs, but there is also no risk of the fitter picking up the wrong product.

Are multiple combinations possible with the M-Series?

Yes, thanks to the SCS connection technology, the M-Series boxes can be easily and securely lined up at a standardized distance of 71 mm.

Can the installation of the M1 be extended unlimited?

For more installation space in the box or for exact positioning of the conduit entry, the Push-on Frame is mounted directly onto the M1. The Frame was also designed with SCS connection technology to ensure a consistently stable connection for multiple boxes.

How is the conduit prevented from slipping out of the box during concreting?

Thanks to the conduit grip of the membrane boxes, they are absolutely concrete-tight and ensure reliable strain relief.

Does the conduit grip also work with coated concrete pipes?

Yes, it works perfectly. We recommend our concrete pipe as the perfect combination for the Primo concrete construction program.

Are component parts such as a conduit coupling required when inserting (several) conduits?

Can the membrane technology withstand the pressure of concrete?

Yes, it’s been tested. We also have many satisfied customers who use our concrete boxes.

How are the M-Series boxes attached to the formwork?

The M-Series boxes can be positioned using magnets (manually or with a robot), glued in the classic way or attached to the reinforcement with the Wings.

How can the M-Series boxes be attached to the formwork-free side during solid wall production?

There are two options: You use the M-series Wings or the Extension units.

Does the Wings hold on the M-Series?

Yes, the Wings hold on to all Primo concrete products: Membrane Boxes, Installation Housings, Universal Junction Boxes, Grommets, Sleeves and Wall and Ceiling Transitions.

What are the advantages of the XL installation housing?

Take the product out of the box, place it on the formwork and you’re done! The XL installation housings are absolutely concrete tight, mounted in seconds and offer numerous possible applications. They are perfect for mounting all special installation housings – from luminaires to loudspeakers to other built-in components. The probably greatest advantage for precast factories: The XL 200 and the XL 250 can be attached with a magnet. This saves a lot of time in production and also delivers a high-quality product. The perfect material for your perfect precast part and a satisfied customer.

Is it possible to vary the installation height of the XL installation housing?

The XL 150 Extension Ring and the XL 200 Extension Ring are available for the XL 150 and XL 200 installation housing. The Extension Ring can be attached to the installation housing and provides more installation space thanks to the increase in height. As many Extension Rings can be connected together until the desired installation depth is reached. The plug-in system ensures a quick and stable connection.

Is it possible to add a transformer tunnel to the installation housings of the XL-Series?

Yes, an optional Universal Tunnel is available for the XL 150, XL 200, and XL 250 installation housings. The Universal Tunnel creates additional installation space, ideal for larger electronic components, for example. It can be universally attached to all installation housings in the XL-Series.

The XL 300 installation housing is available in two versions: One with transformer tunnel and one without transformer tunnel.

Can the XL-Series be used for the production of exposed concrete?

Yes, the XL-Series is ideal for exposed concrete. Depending on the area of application, you can choose the right Front Part individually.

Why is the cover removable?

The removable cover allows cables and conduits to be pulled into the installation housing before concreting. Thanks to the integrated membrane sealing lip, everything remains absolutely concrete-tight.

How are the XL-Series installation housings attached to the formwork?

The installation housings of the XL-Series can be positioned using magnets (manually or with a robot) or glued in the classic way.

What are the advantages of Primos Standardised Special Installation Housings?

With the Schalfix and the Ventilation Sleeve, you save an enormous amount of time when creating recesses. Henceforward the time-consuming creation of individual wooden or foam polystyrene recesses belongs to the past. The Ventilation Sleeve is ideal for ventilation recesses, while the Schalfix is recommended for all other areas of application.

Are there different sizes of the Ventilation Sleeve?

No, as almost only DN 125 domestic ventilation systems are installed. The Primo Ventilation Sleeve is perfect for this.

How are the Standardised Special Installation Housings attached to the formwork?

The Schalfix is glued in the classic way, the Ventilation Sleeve can be glued or placed using magnets.

Do you have any questions about our products? We are there for You