THE PRIMO EQUIPMENT CARRIER

One cover, many advantages

Many advantages

The Primo Equipment Carrier

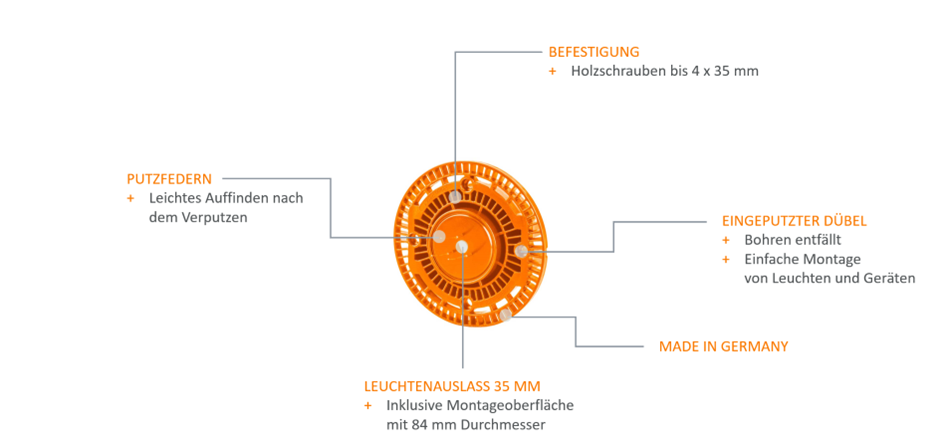

With the “plastered-in dowel” from Primo, the Equipment Carrier GET-80, the drill has a break for a while. Because today’s electrician screws the mounting plate of luminaires directly to the Equipment Carrier – without drilling and inserting dowels! The cover is attached onto the inserted flush-mounting box with two screws and the wall is plastered.

The installation surface of the Equipment Carrier was designed with various openings. Luminaires and other devices with screws up to 4 mm in diameter can be mounted on the Equipment Carrier without drilling and setting dowels, thus saving time and costs. Let’s not forget, of course, that due to the careful design of the matching Thermo Boxes, all cables and conduits are inserted in the rear part of the box. This guarantees that no cables or conduits are damaged during luminaire assembly.

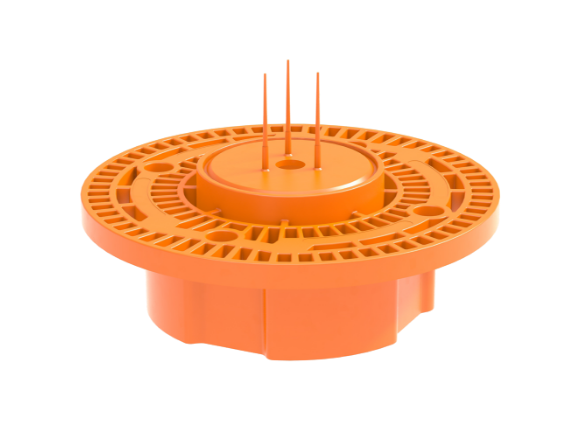

Equipment Carrier GET-80

The GET-80 Equipment Carrier is an attachment for the flush-mounting boxes of the Primo Thermo Box Series and for the concrete boxes of the M1 Membrane Box Series. With a large mounting surface of 84 millimeters, the appliance holder becomes an outlet including mounting surface, so that the appliance holder can be screwed in without dowels – quite simply without time-consuming drilling!

Downloads:

EQUIPMENT CARRIER FROM PRIMO

All advantages at a glance!

Easy installation

in just a few steps

1

Mark the first box and drill with the Primo High Speed Driller a 82 mm hole.

2

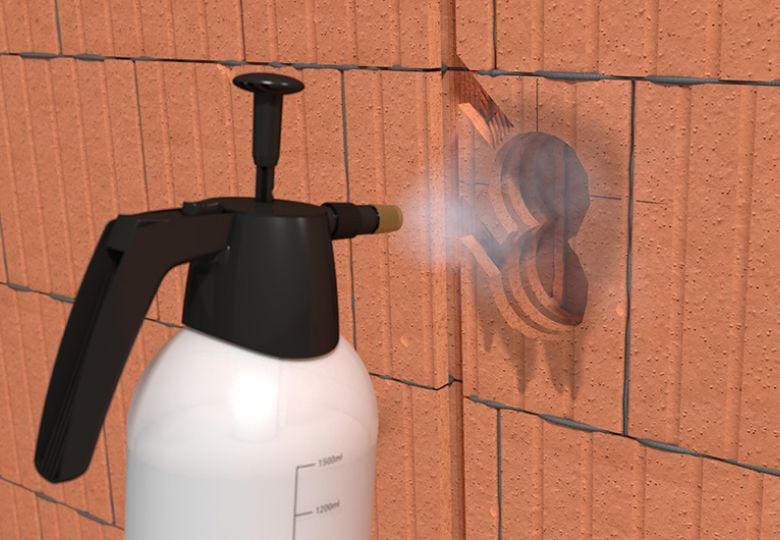

Moisten the hole so that the foam swells better.

3

Break off the plaster stop of the Thermo Box.

4

Foam the box.

5

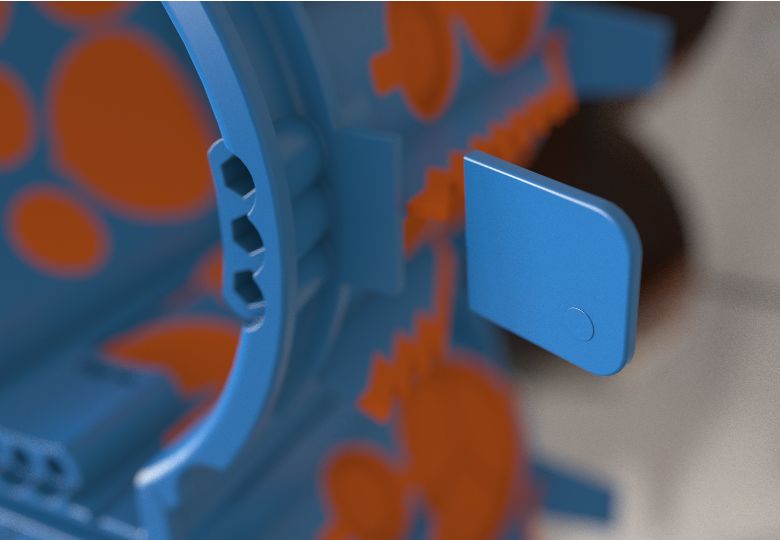

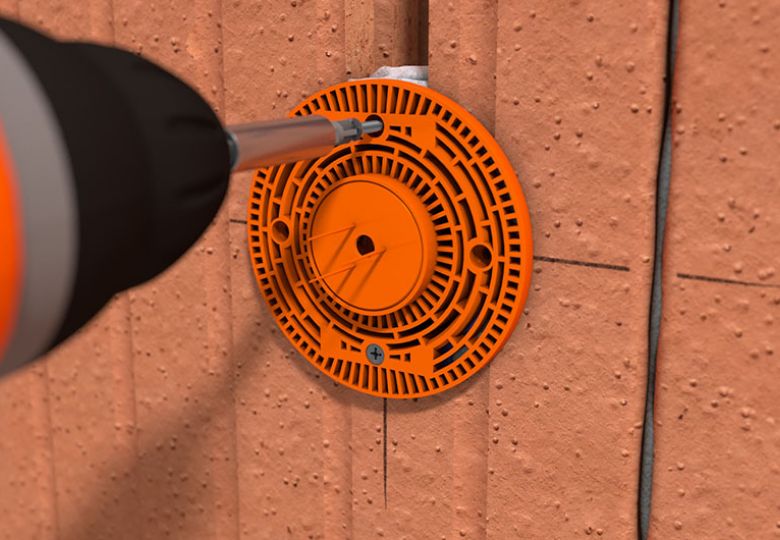

Push on the Equipment Carrier and fasten it with 2 screws.

6

Easy to find after plastering thanks to the signal pins. Tap them in carefully with the hammer.

7

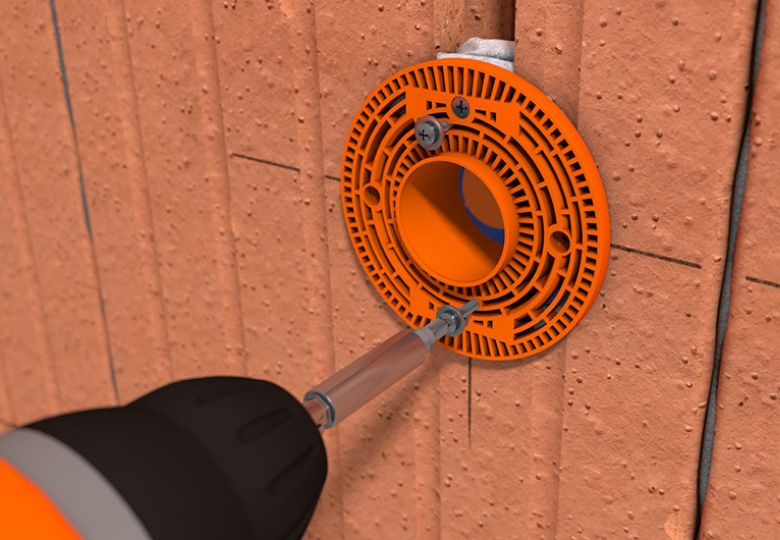

Screw the lamp holder through the plaster without dowels.

8

There is a suitable opening and foothold for screws in the Equipment Carrier.

9

Fasten the lamp or device directly.

Accessories for the fastest flush-mounting system in the world

YOU MIGHT ALSO BE INTERESTED IN:

Further flush-mounting solutions

What do you need the the Equipment Carrier for?

The Equipment Carrier is a luminaire outlet, including an 84 mm mounting surface. It is plugged onto the Thermo Box or the M1. The device holder is then screwed in place without the need for dowels or drilling. The Equipment Carrier is also suitable for luminaires with narrow mounting bases. It also serves as a signal cover during plastering, thus protecting the interior of the box from dirt.

Do you have any questions about our products? We are there for You